BACKGROUND:

Placement of this cover feature article in Machinery Lubrication

resulted from planning and writing a feature with strong

reader interest with close, collegial communications with the

magazine's very professional Managing Editor,

Jenny

Kucera

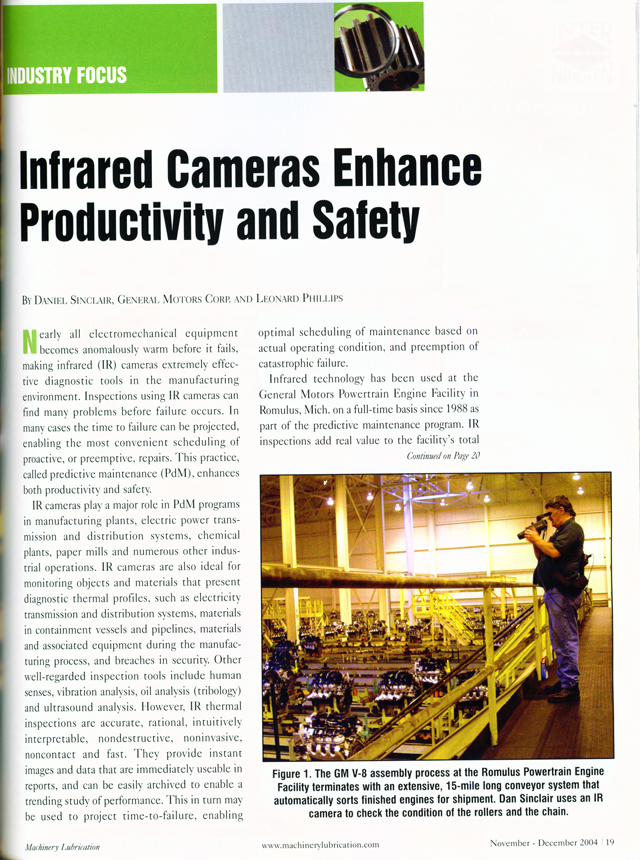

I wrote this article with Dan Sinclair of General Motors after touring and photographing the General Motors Romulus, Michigan, Powertrain Engine facility with Dan, who is a maintenance engineer and a Master Electrician. The tour was something I had wanted to do for some time to provide a fresh marketing tool for FLIR Systems involving a key customer. I have a strong avocational interest in cars. The opportunity of teaming with the FLIR trade show booth at the SAE Annual Meeting in Detroit brought me within a fast drive to Romulus and a very fruitful tour and interview.

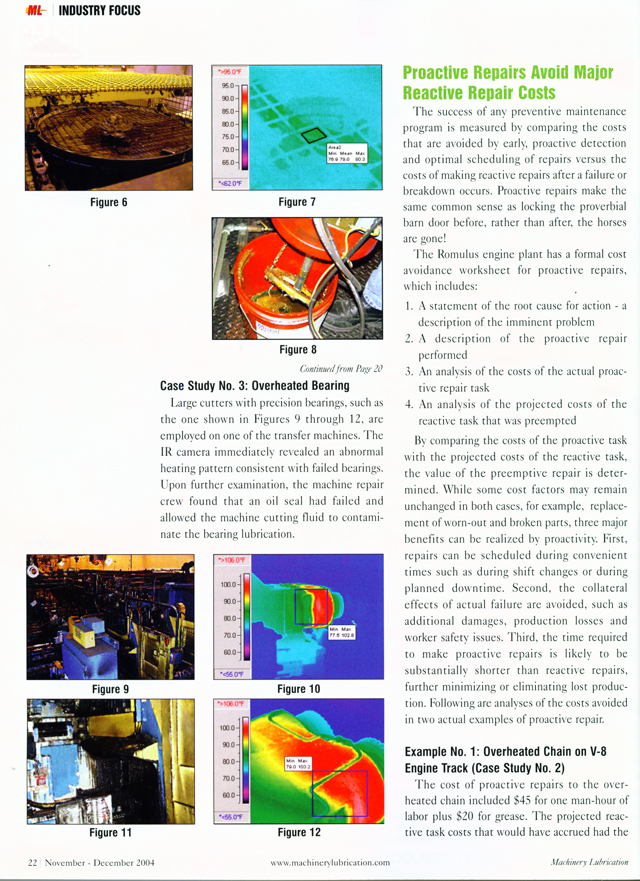

What I found during the tour is that Dan is saving General Motors many, many thousands of dollars each year by providing predictive maintenance information using a FLIR infrared camera. Dan locates thermal anomalies in electrical and mechanical equipment that indicate problems. He then schedules repairs during planned downtime, often during a shift change, unless safety demands more immediate action. In one case, as is covered in the article, one of his findings preempted a potential loss of $1 million in repairs and lost production! I was pleased also to contribute the cover photo and many of the other photographs appearing in the publication.— Leonard A. Phillips